gräfix 76 white

Adhesive and coating mortar white

CS IV - white, for gräfixtherm ETIC systems

The dispersion-modified thin-bed mortar with processing-enhancing additives is primarily used for bonding and coating gräfix rigid polystyrene foam and other rigid foam, mineral fibre and soft wood fibre boards or similar in the entire thermal insulation sector. As a coating mortar, it is ideally suited for embedding reinforcing mesh due to its high elasticity. After drying, the applied plaster layer can easily be coated with a thin layer of finishing plaster. We generally recommend priming the surface with RABOLIN 160 Render Primer before applying the render.

Yield: 24 litres of fresh mortar from a

30 kg bag with 8 litres of water

Delivery: 30 kg bag

- White standard render mortar according to DIN EN 998-1

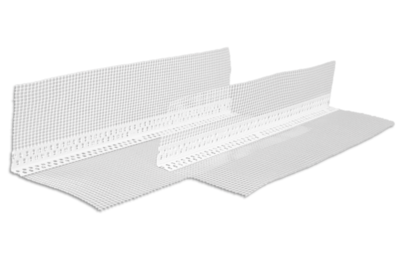

- for external thermal insulation composite systems

- for fabric levelling, e.g. as weather protection

- Compressive strength: CS IV

- approx. 24 litres of fresh mortar

- approx. 800 litres/to

- Processing time approx. 2 hours (depending on weather conditions)

- Delivery in 30 kg paper bag

- 40 bags per pallet/1.20 tonnes

For thermal insulation composite system approvals:

Z-33.41-208 ETICS polystyrene bonded

Z-33.43-207 ETICS - polystyrene and mineral wool bonded and dowelled

Z-33.47-660 ETICS - soft wood fibre

- Suitable for polystyrene, mineral fibre, soft wood fibre boards, etc.

- Can be applied by hand or with a plastering machine

- Very good machinability due to processing-enhancing additives

- Can be used indoors and outdoors and in damp rooms

- also ideal for fabric levelling

- Remove unsound coatings

- Roughen and clean old, dispersion-bound substrates (plaster or paint)

- Mix one bag of gräfix 76 with approx. 8 litres of water

- Stir well and stir again after 10 minutes

- when applying with a plastering machine, work with a remixer

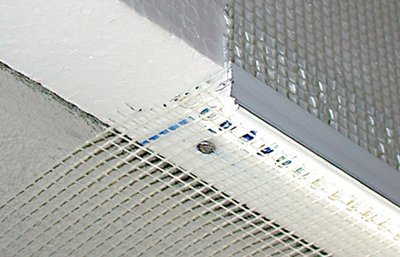

- Adhere using the point-bead method or over the entire surface using a notched trowel

- Coating layer on insulation boards at least 4 mm (recommended: 5 mm)

- Embed gräfix 791 ETICS fabric in the upper third

- Smooth the surface with the smoothing disc

- Yield: with 4 mm plaster thickness approx. 6 m² per bag

Requirement:

For bonding: approx. 4.0 kg/m²

For reinforcement: approx. 4.5 kg/m²

- Technical data sheet ► (EN)

- Safety data sheet ► (DE) - (EN)

- Declaration of performance ► (DE)

- Brochure "External thermal insulation composite systems"

- Brochure "Processing guidelines - ETICS"

- Brochure "Improved fire protection for external thermal insulation composite systems with EPS"

External thermal insulation composite systems

Energy saving & environmental awareness

The shortage of fossil fuels and the emission of harmful carbon dioxide demand solutions and call for sustainable action.

It is time to act!

The annual increase in energy requirements and the parallel rise in CO2 emissions from uninsulated residential buildings call for functional insulation. The opportunity here lies in the necessity.

Thermal insulation not only leads to high energy and cost savings, it also promotes energy savings.

All in all, thermal insulation increases the value of the property and presents itself as an attractive savings investment in these uncertain times.

Experience a healthy, feel-good climate with gräfix-therm thermal insulation composite systems.

The different insulation board materials can be coated in a variety of colours and textures. This means that an individual and appealing look can be realised for every building.

Combined with a coating from the "gräfix lime line" product range, the indoor climate in the living area can be significantly improved.